Component Washing Machine Manufacturers in India

In today's fast-paced manufacturing world, cleanliness is crucial for efficiency and product quality. As one of the leading component washing machine manufacturers in India, we provide high-performance, component washing machines tailored to meet the diverse needs of industries such as automotive, aerospace, electronics, and medical equipment. Our machines are designed to remove oil, grease, dirt, and contaminants with precision, ensuring your components meet the highest cleanliness standards.

Types of Component Washing Machines we offer:

As one of the leading component washing machine manufacturers in India, we specialize in delivering high-quality industrial washing solutions designed to meet diverse cleaning requirements. Our advanced range of component washing machines ensures precision, efficiency, and reliability across various industries. We offer different types of machines, each engineered for specific applications:

Front Load Component Washing Machine

Built for ease of loading and unloading, the front load component washing machine is perfect for heavy parts that require thorough cleaning. Its ergonomic design ensures smooth operation while saving floor space.

Top Load Component Washing Machine

Ideal for compact setups, the top load washing machine allows components to be loaded directly from the top. It is suitable for smaller parts and offers efficient cleaning without compromising quality.

Conveyorised Component Washing Machine

Designed for continuous operations, the conveyorised washing machine is best suited for high-volume industries. It moves components along a conveyor belt through different cleaning, rinsing, and drying stages, ensuring consistent results.

Multistage Conveyorised Component Washing Machine

When components need multiple cleaning and treatment stages, our multistage conveyorised machines are the right solution. They integrate processes like washing, rinsing, and drying in a seamless flow, enhancing productivity.

Single Component Washing Machine

Engineered for precision, the single component washing machine is tailored for cleaning individual parts that require focused and detailed washing cycles.

Small Component Washing Machine

Perfect for delicate and compact items, this machine provides gentle yet effective cleaning for small parts used in industries like electronics, medical, and precision engineering.

Rotary Indexing Component Washing Machine

This system rotates parts through various cleaning stations in a circular indexing mechanism. It ensures accuracy and reduces cycle time, making it ideal for high-precision applications.

Cage Rotation Component Washing Machine

For bulk parts that require uniform cleaning, the cage rotation washing machine is highly efficient. Components are loaded into a rotating cage, ensuring every surface is cleaned thoroughly.

Single Chamber Multi-Process Roatry Basket Component Washing Machine

Compact yet versatile, this machine combines multiple cleaning processes in a single chamber. With a rotary basket design, it provides consistent cleaning results while optimizing space.

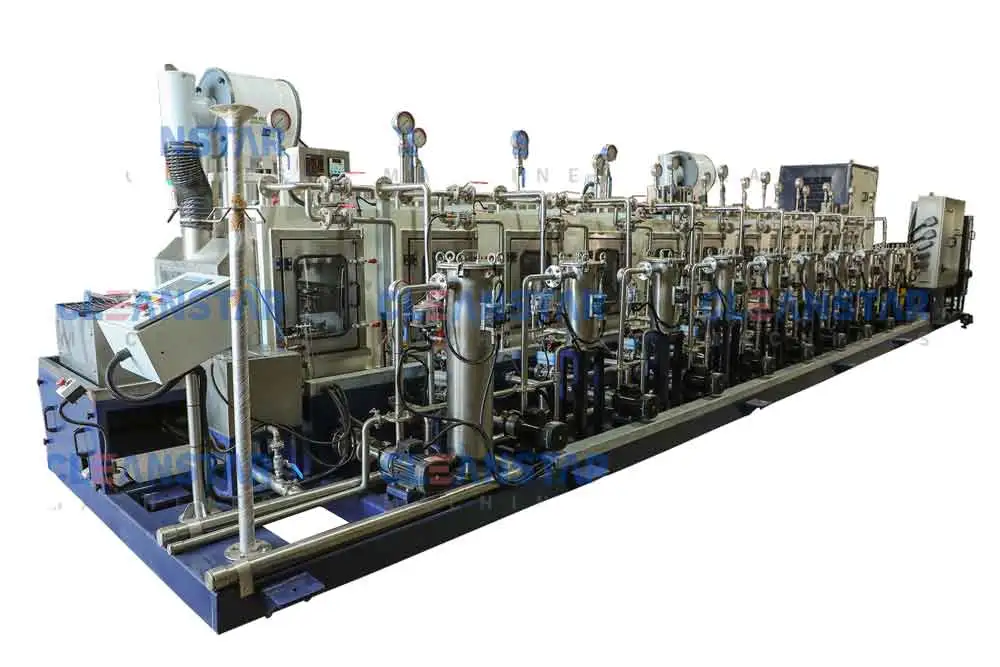

Indexing Multistage Conveyorised Component Washing Machine

This advanced system combines indexing and multistage conveyor technology, allowing components to be processed through various cleaning stages with precise control, ideal for complex industrial requirements.

Industrial Component Washing Machine

Our industrial component washing machines are engineered for large-scale operations where reliability and durability are key. Built to handle heavy workloads, they provide consistent cleaning performance for a wide range of industrial components.

What is a Component Washing Machine?

A component washing machine is an industrial cleaning system designed to remove contaminants such as oil, grease, dust, dirt, and metal shavings from machine parts and components. These machines use various cleaning methods, including spray washing, ultrasonic cleaning, and immersion cleaning, to ensure thorough cleanliness.

As a leading component washing machine manufacturer in India, we provide customized and high-performance cleaning solutions to enhance productivity and ensure compliance with industry cleanliness standards.

Component washing machines play a pivotal role in the meticulous process of ensuring optimal cleanliness and functionality of various components across industries. These cutting-edge machines are the cornerstone of component cleaning, providing an efficient and thorough means of washing intricate parts to meet stringent quality standards. As the demands for precision and reliability escalate across manufacturing sectors, the significance of industrial parts washing machines becomes increasingly pronounced.

Why Choose Our Component Washing Machines?

We specialize in developing component washing machines with advanced ultrasonic, spray, and immersion cleaning technologies. Whether you require a compact unit for small parts or a fully automated system for large-scale cleaning, our solutions offer:

- Efficient Contaminant Removal : Our machines ensure deep cleaning, eliminating even the finest particles.

- Customizable Solutions : We design machines to suit your specific cleaning needs, from batch washing to conveyor-type systems.

- Energy-Efficient Performance : Optimized water and chemical usage for cost-effective and eco-friendly operations.

- Durability and Reliability : Built with high-grade materials to withstand industrial demands.

Your Reliable Component Washing Machine Manufacturers

We are committed to delivering cutting-edge component washing machines that enhance productivity, meet strict quality standards, and improve operational efficiency. Whether you require a standalone washer or an integrated cleaning system, our expertise ensures the perfect solution for your needs.

We're creators of precision and efficiency. As manufacturers of component washing machines in pune, we don't just craft machines; we engineer solutions that elevate industries. Our commitment lies in perfecting the art of cleanliness, ensuring that every component, no matter how intricate, emerges spotless and primed for peak performance. With a blend of cutting-edge technology and relentless innovation, our machines aren't mere appliances; they're the cornerstone of reliability, designed to meet the diverse needs of modern manufacturing. We take pride in being the driving force behind cleaner, more efficient production lines, empowering businesses to deliver excellence with every component they produce.Furthermore, the evolution of component washing machines is not stagnant; it's a dynamic process. Continuous research and development efforts drive the innovation curve forward.

Find the Right Component Washing Machine for Your Needs

From single-chamber washing systems to multistage automated solutions, we offer a wide range of component washing machines to fit different industrial applications. Our team of experts is ready to assist you in selecting the perfect machine for your requirements.

Looking for the best component washing machine manufacturers? Get in touch with us today to find the ideal cleaning solution for your industrial parts.