Conveyorised Industrial Parts Washer Machine

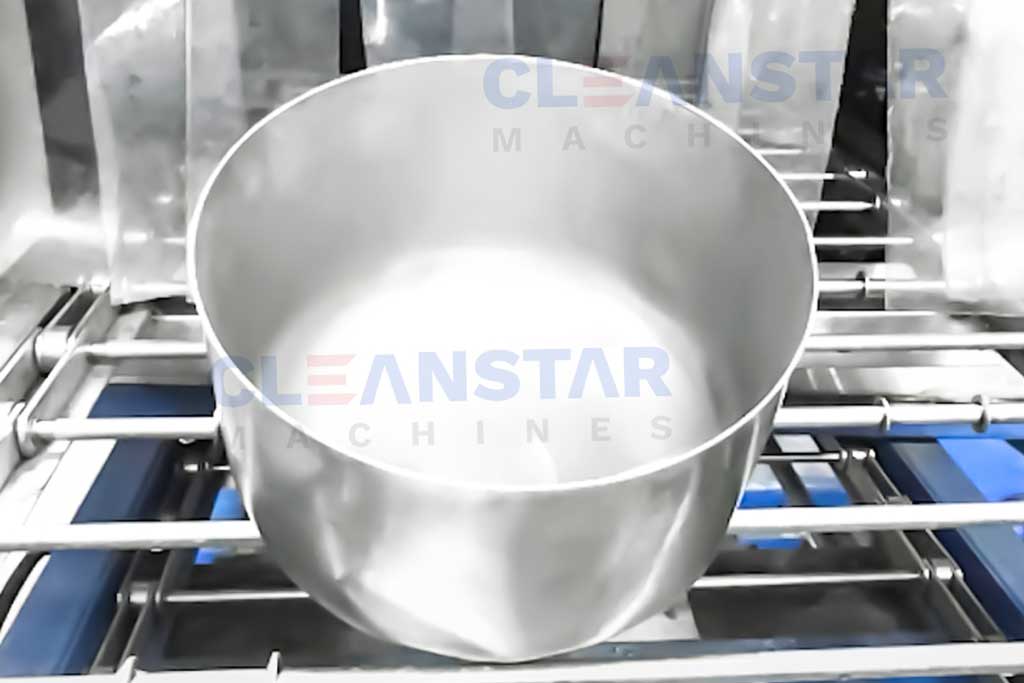

Our Multi Stage Conveyor-Type industrial parts washing machine is designed for the thorough and efficient cleaning of various components and parts in a production or manufacturing setting. These machines use a conveyor system to move parts through multiple cleaning stages, ensuring that they are properly cleaned and prepared for further processing, assembly, or use.

The Multistage conveyor parts washer represents a remarkable advancement in industrial cleaning technology, offering an efficient and comprehensive solution to the increasingly complex requirements of component cleaning. This cutting-edge system is designed to meet the needs of diverse industries, from automotive to electronics, and beyond.The machine utilizes a series of conveyor belts to transport components through various cleaning stages, each tailored to address specific contamination challenges.

The working of this innovative industrial parts washer machine begins with the loading of components onto the conveyor, which then guides them through a sequence of meticulously engineered cleaning stages. These stages can include processes such as pre-washing, degreasing, ultrasonic cleaning, rinsing, drying, and even inspection. At each stage, the components are subjected to specialized cleaning techniques and solutions, ensuring that contaminants like oils, greases, dust, and particulates are thoroughly removed. The modular nature of the multistage system allows for customization, enabling manufacturers to adapt the machine to the unique cleaning requirements of their components.

A conveyorised parts washer machine is a cutting-edge solution designed to efficiently clean industrial components of various sizes and shapes. This machine uses a continuous conveyor system to move parts through different cleaning stages, ensuring consistent and thorough cleaning results. It is ideal for industries where large-scale or batch cleaning is required, such as automotive, aerospace, and manufacturing. The conveyor system eliminates manual handling, enhancing productivity and reducing labor costs.

At our facility, we manufacture high-quality conveyorised parts washer machines tailored to meet the unique requirements of various industries. Our machines are engineered with precision to ensure reliable performance and long-term durability. The cleaning process in our machine typically involves multiple stages, such as pre-washing, washing, rinsing, and drying. Each stage is carefully calibrated to deliver superior results, whether removing grease, oil, dirt, or other contaminants. The conveyor system is adjustable and can be customized to accommodate parts of different sizes and weights, ensuring flexibility and efficiency in operations. We use robust materials and advanced technology to construct our machines, making them suitable for harsh industrial environments. Our machines are designed with energy-efficient components to reduce operational costs while maintaining high cleaning standards. Safety features and easy-to-use controls ensure smooth operation and minimal downtime.

Our Industrial Parts Washer Machine is engineered to deliver high-performance cleaning solutions for industries requiring thorough and consistent degreasing, dirt removal, and contaminant elimination from metal and non-metal parts.

Designed with advanced cleaning technologies, including ultrasonic, spray, and immersion washing, our machine effectively removes oil, grease, rust, carbon deposits, and other residues that compromise component integrity. Whether used in automotive, aerospace, engineering, or heavy machinery sectors, this industrial-grade washer enhances product longevity, reduces maintenance downtime, and improves overall efficiency.

Built with robust construction and customizable features, our industrial parts washer is tailored to meet diverse cleaning requirements, ensuring environmentally friendly operation with minimal water and chemical usage. From small precision parts to large industrial components, our cleaning system guarantees exceptional results, optimized workflow, and cost savings for your business.

In the dynamic landscape of modern manufacturing processes, the demand for efficient and reliable industrial parts washing machines has never been higher. Among the array of options available, multistage conveyor-type industrial parts washer machines stand out as a cornerstone of precision and effectiveness. These machines play a pivotal role in ensuring the cleanliness and quality of industrial components, contributing significantly to the overall manufacturing excellence.

At the heart of this cutting-edge technology is the industrial parts washing machine, a robust and sophisticated system designed to meet the stringent cleanliness standards required in various industries. The industrial conveyor parts washer machines are equipped with multiple stages, each serving a unique purpose in the thorough cleaning and drying of intricate components. Let's delve into the intricate workings of these machines and explore how they revolutionize the industrial cleaning process.

The industrial conveyor parts washer, a key component of this system, serves as the backbone for the seamless movement of components through the cleaning stages. This conveyor system is meticulously designed to handle diverse shapes and sizes of industrial parts, ensuring uniform cleaning and drying throughout the process. The efficiency of the conveyor parts washer is enhanced by its ability to transport parts through a series of stages, optimizing the use of cleaning agents, water, and energy.

In the first stage of the multistage conveyor-type industrial parts washing machine, components are subjected to a pre-wash cycle. This initial phase involves the removal of coarse contaminants such as grease, oil, and surface debris. The industrial parts washer and dryer work in tandem during this stage, ensuring that the components emerge from the pre-wash cycle in a state ready for the subsequent cleaning phases.

As the components progress through the conveyor system, they enter the main wash stage. Here, the industrial parts washer machine deploys specialized cleaning solutions, often tailored to the specific requirements of the manufacturing process. High-pressure jets, brushes, and immersion methods work synergistically to eliminate stubborn contaminants and residues, leaving the components immaculately clean.

Following the main wash stage, the industrial conveyor parts washer guides the components through a rinse cycle. This crucial step ensures the removal of any remaining cleaning agents or contaminants from the surface of the parts. The rinse water used in this stage is often filtered and recycled, contributing to the sustainability of the cleaning process.

Once the components have undergone the thorough cleaning stages, they enter the drying phase facilitated by the industrial parts washer and dryer. This stage utilizes advanced drying techniques such as hot air blowers, infrared radiation, or vacuum drying to eliminate any residual moisture, leaving the components completely dry and ready for the next stages of the manufacturing process.

One of the notable advantages of multistage conveyor-type industrial parts washing machine is their adaptability to different industries and applications. Whether it's automotive, aerospace, electronics, or any other manufacturing sector, these machines can be customized to meet the unique cleaning requirements of diverse components. The flexibility of the industrial parts washer machines ensures that manufacturers can achieve the desired cleanliness standards without compromising efficiency or productivity.

Moreover, the integration of advanced technologies, such as automation and digital controls, enhances the precision and repeatability of the cleaning process. Industrial conveyor parts washers can be programmed to accommodate various part geometries and cleaning specifications, providing manufacturers with a versatile and reliable solution for their specific needs.

In conclusion, multistage conveyor-type industrial parts washing machines represent a pinnacle of efficiency and reliability in the realm of industrial cleaning. The industrial conveyor parts washer machines, with their intricate cleaning stages and conveyor systems, play a pivotal role in ensuring the quality and cleanliness of components in diverse manufacturing sectors. As industries continue to evolve, these advanced cleaning solutions stand as a testament to the commitment to excellence in manufacturing processes, setting new standards for cleanliness, precision, and productivity.

State-of-the-Art Cleaning Solution

Multistage Cleaning Process

Continuous Conveyor System

Modular Design

Advanced Filtration and Recycling

Precision Cleaning

Compliance with Industry Standards