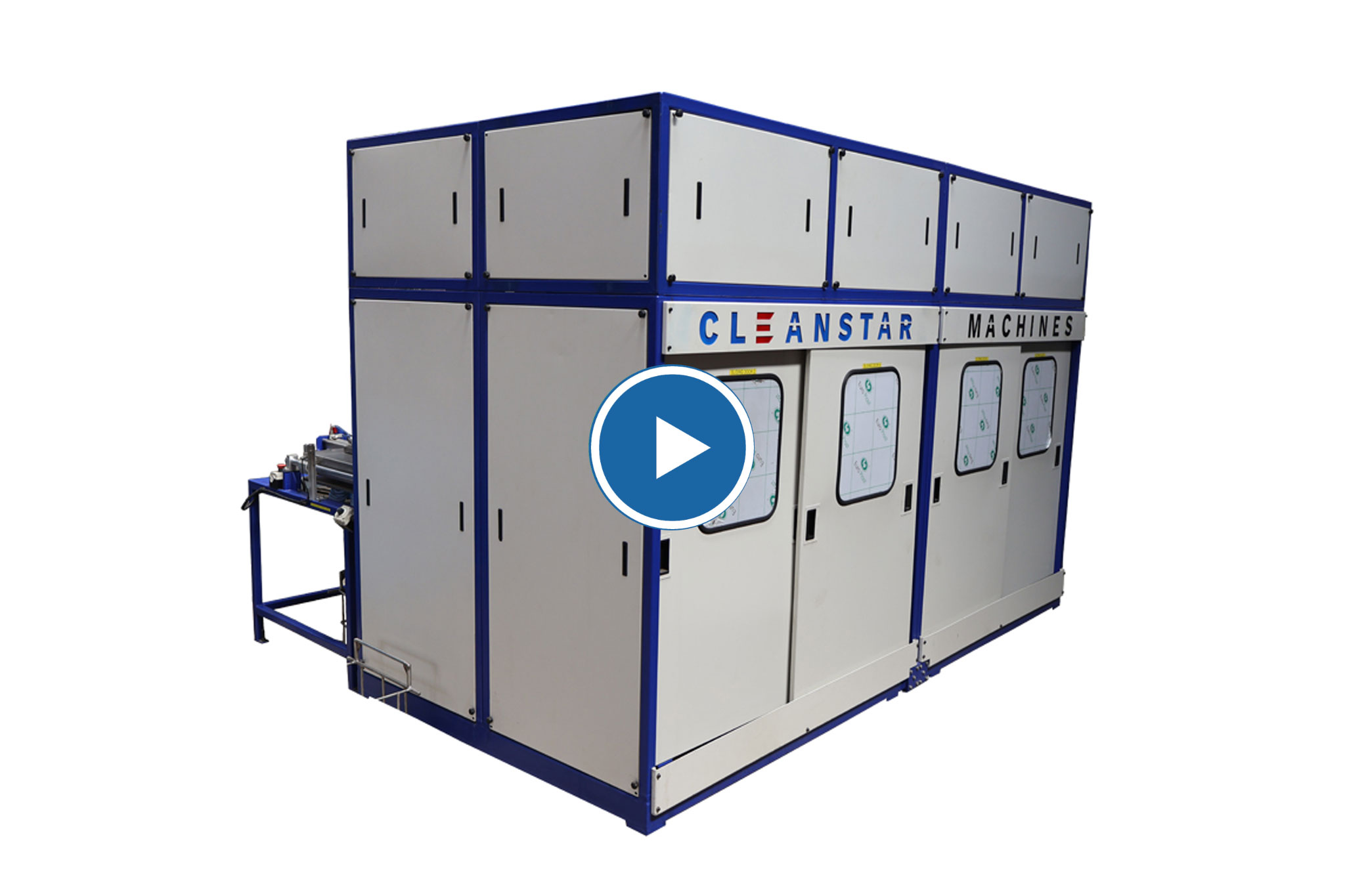

Ultrasonic Cleaning Machine Manufacturers in Pune, India – High-Performance Cleaning Solutions

Cleanstar Machines is a trusted manufacturer of ultrasonic cleaning machines and an authorized AMC & service provider in Pune., offering reliable and advanced cleaning solutions for different industries. Our ultrasonic cleaning machines work on the principle of high-frequency sound waves, which create tiny bubbles in a liquid. These bubbles collapse with force, removing dirt, oil, and other contaminants from the surface of objects placed in the tank. This technology ensures deep and thorough cleaning of items that are often difficult to clean with traditional methods. Whether it’s delicate jewelry, precision medical instruments, or heavy industrial components, our machines deliver safe, fast, and effective cleaning results.

Working Principle of our Ultrasonic Cleaning Machine

Our ultrasonic cleaning machine works on an advanced cleaning technology that uses ultrasonic sound waves and cleaning solutions to remove dirt, grease, oil, and contaminants from intricate surfaces. The process ensures deep cleaning of even the most complex parts, which traditional cleaning methods cannot reach. The working principle is explained below in detail:

- Generation of Ultrasonic Waves: The machine consists of ultrasonic transducers that are attached to the cleaning tank. When the machine is switched on, these transducers convert electrical energy into high-frequency ultrasonic sound waves (usually ranging between 20 kHz to 40 kHz). These waves travel through the cleaning liquid and initiate the ultrasonic cleaning process.

- Cavitation Process Begins: As the ultrasonic waves pass through the liquid, they create millions of microscopic vacuum bubbles. This phenomenon is known as cavitation. These bubbles rapidly form and collapse at an extremely high speed, producing powerful cleaning forces within the liquid medium.

- Impact of Bubble Implosion: When the cavitation bubbles collapse, they release high-energy shock waves and microjets. These implosions generate intense localized pressure and temperature, effectively dislodging and removing oil, grease, dust, rust, and carbon deposits from the surface of the components being cleaned.

- Deep Penetration into Complex Geometries: The high-frequency sound waves penetrate deeply into blind holes, crevices, fine threads, and hidden surfaces, ensuring complete cleaning of components. This makes ultrasonic cleaning ideal for automotive, aerospace, medical, and precision engineering industries, where component cleanliness is crucial.

- Use of Suitable Cleaning Solution: A specially formulated ultrasonic cleaning solution or detergent is used in the tank, depending on the type of contamination and material of the component. The cleaning solution enhances the cavitation effect and helps in dissolving or loosening contaminants effectively.

- Rinsing and Drying Process: After ultrasonic cleaning, the parts are transferred to a rinsing stage to remove any remaining residues. Finally, a hot air drying system ensures that all moisture is completely removed, leaving the components clean, dry, and ready for use or assembly.

- Final Output – Perfectly Clean Components: The end result is thoroughly cleaned components with no residues, grease, or particles. The process is efficient, eco-friendly, and consistent, ensuring uniform cleaning quality every time.

Types of Ultrasonic Cleaning Machine

At Cleanstar Machines, we offer a wide range of ultrasonic cleaning machines to cater to diverse industrial, medical, and commercial cleaning needs. As a trusted ultrasonic cleaning machine provider in Pune, our machines are designed for efficiency, precision, and reliability. Here are the main types we offer:

- Multistage Ultrasonic Cleaning Machine: These machines feature multiple cleaning and rinsing stages, ensuring thorough and sequential cleaning of parts. Ideal for complex components that require step-by-step cleaning and drying processes.

- Conveyorised Ultrasonic Cleaning Machine: Designed for high-volume production environments, these machines use conveyor systems to continuously move parts through ultrasonic cleaning tanks, improving productivity and consistency.

- Ultrasonic Engine Parts Cleaning Machine: Specifically built for automotive and industrial engine components, these machines remove grease, oil, carbon deposits, and dirt from engine parts efficiently without causing any damage.

- Ultrasonic Washing Machine: Suitable for general-purpose cleaning, these machines are versatile and can clean a variety of items with precision, saving time and effort compared to manual cleaning.

- Ultrasonic Cleaning Equipment / Systems: These are comprehensive cleaning setups that include tanks, heaters, ultrasonic generators, and control units, designed for different industrial and commercial applications.

- Industrial Ultrasonic Cleaning System: Heavy-duty ultrasonic systems for large-scale industrial parts cleaning. These machines handle large and heavy components while maintaining precise cleaning quality.

- Jewellery Ultrasonic Cleaner: Perfect for cleaning delicate jewelry, watches, and ornaments. These machines remove dirt and grime without scratching or damaging precious metals or stones.

- Ultrasonic Cleaner for Surgical Equipment: Designed for medical and laboratory use, these machines ensure safe and effective cleaning of surgical instruments, ensuring hygiene and precision.

- Plastic Ultrasonic Turbine Washer: Specialized ultrasonic machines for cleaning plastic components and turbine parts, ideal for industries like automotive, aerospace, and engineering.

Benefits of our Ultrasonic Cleaning Machine

- Deep and Thorough Cleaning: Our ultrasonic cleaning machines use high-frequency sound waves that generate microscopic bubbles. These bubbles penetrate into the tiniest gaps, corners, and complex geometries of parts, ensuring a level of cleanliness that traditional cleaning methods cannot achieve.

- Safe for Delicate Surfaces: Unlike harsh scrubbing or abrasive cleaning, ultrasonic cleaning is gentle yet effective. It removes dirt, grease, and contaminants without causing scratches or damage, making it ideal for sensitive items such as jewelry, medical instruments, and precision components.

- Time-Saving Process: Manual cleaning takes time and effort, while our ultrasonic cleaning machines complete the job quickly and efficiently. This helps businesses improve productivity and reduce downtime.

- Eco-Friendly and Cost-Effective: The process uses less water and fewer chemicals compared to conventional cleaning methods. This not only lowers operational costs but also makes it a more environmentally responsible choice.

- Consistent and Reliable Results: Our machines deliver uniform cleaning results every time, eliminating the variations that often come with manual cleaning. This ensures better quality and reliability in your operations.

Features of Ultrasonic Cleaning Machine

As one of the leading ultrasonic cleaning machine manufacturers in Pune, our machines are designed with advanced features to provide efficient, safe, and reliable cleaning for a wide range of applications:

- High-Frequency Ultrasonic Technology: Our machines use ultrasonic waves above 20 kHz to create cavitation bubbles in the cleaning solution. This ensures deep and thorough cleaning of even the most intricate parts without damaging delicate surfaces.

- Durable Construction: Built with high-quality stainless steel tanks and robust outer frames, our machines are long-lasting and resistant to corrosion, ensuring reliable operation in industrial environments.

- Adjustable Cleaning Parameters: Users can easily control the cleaning time, temperature, and ultrasonic frequency according to the type of items being cleaned, allowing precise and customized cleaning results.

- Efficient Heating System: Many of our models come with built-in heaters that accelerate the cleaning process, improving efficiency and saving time.

- User-Friendly Interface: Simple control panels with digital displays make our ultrasonic machines easy to operate, reducing errors and training time.

- Energy-Efficient Operation: Designed to consume minimal power without compromising performance, these machines are both cost-effective and environmentally friendly.

- Safety Features: Equipped with overheat protection, auto shut-off, and secure lids, our ultrasonic cleaning machines ensure safe operation for users and the equipment.

Aplications of Ultrasonic Cleaning Machine

Ultrasonic cleaning machines are highly versatile and widely used across various industries for precise and efficient cleaning. These all types of ultrasonic cleaning machines are majorly in demand from large industrial sectors such as:

- Automotive Industry: Ultrasonic cleaning machines are used to clean engine parts, gears, and other precision components. They remove oil, grease, carbon deposits, and other contaminants without damaging delicate surfaces.

- Medical and Healthcare Sector: Surgical instruments, laboratory equipment, and delicate medical tools are cleaned thoroughly using ultrasonic technology, ensuring hygiene and safety.

- Jewelry and Watchmaking: Ultrasonic cleaners are ideal for removing dirt, grime, and polishing jewelry, watches, and ornaments without scratching or harming precious metals or stones.

- Aerospace and Engineering: Industrial parts, turbine blades, and precision components are cleaned efficiently using industrial ultrasonic cleaning systems, ensuring optimal performance and longevity.

- Electronics and Manufacturing: Small electronic components, circuit boards, and machined parts are cleaned precisely, reaching intricate areas that are difficult to clean manually.

- Food and Beverage Industry: Ultrasonic cleaning equipment helps in cleaning machinery, trays, and containers, maintaining hygiene standards and ensuring safe food handling.

- Plastic and Polymer Industry: Components like plastic molds, turbines, and other parts are cleaned efficiently using specialized ultrasonic plastic washers.

At Cleanstar Machines, we are recognized as leading ultrasonic cleaning machine manufacturers in Pune, providing advanced cleaning solutions for a wide range of industries. Our ultrasonic cleaning machines use high-frequency sound waves to create microscopic bubbles in a cleaning liquid, which implode and remove dirt, grease, and other contaminants from parts. This ensures precise and thorough cleaning, even for complex components or delicate items.

We are also a trusted ultrasonic cleaning system manufacturer in Pune, offering machines designed for industrial, medical, and commercial applications. From heavy-duty industrial ultrasonic cleaning systems to delicate jewelry ultrasonic cleaners, our range of equipment meets diverse cleaning requirements. Each system is engineered for efficiency, reliability, and user-friendly operation, helping businesses save time and improve productivity.

Why Choose Cleanstar Machines for Your Ultrasonic Cleaning Needs?

When it comes to ultrasonic cleaning machines, Cleanstar Machines stands out as a trusted name in Pune and beyond. Here’s why customers rely on us for their cleaning solutions:

- Expertise and Experience: With years of experience in manufacturing and servicing ultrasonic cleaning machines, we understand the unique cleaning requirements of various industries. Our expertise ensures you get a machine that delivers precise and efficient cleaning every time.

- Advanced Technology: Our machines incorporate the latest ultrasonic technology, including high-frequency sound waves, multistage cleaning, and energy-efficient designs. This ensures deep, consistent cleaning while being safe for delicate surfaces.

- Wide Range of Solutions: Whether you need industrial ultrasonic cleaning systems, jewelry cleaners, surgical instrument cleaners, or engine parts cleaning machines, we provide solutions tailored to your specific needs.

- Quality and Durability: Built with high-grade materials and robust construction, our ultrasonic machines are designed to last. You can rely on Cleanstar Machines for consistent performance and minimal maintenance.

- Customer Support and AMC: As a reputed ultrasonic cleaning machine provider in Pune, we don’t just sell machines—we provide authorized AMC, maintenance, and service support to ensure your machines run smoothly for years.

- Efficiency and Cost-Effectiveness: Our machines save time, reduce manual effort, and use cleaning solutions efficiently. This results in higher productivity and lower operational costs for your business

FAQs - Ultrasonic Cleaning Machine

What is an ultrasonic cleaning machine?

An ultrasonic cleaning machine uses high-frequency sound waves to create microscopic bubbles in a cleaning liquid. These bubbles implode and remove dirt, grease, and contaminants from parts efficiently and safely.

How does ultrasonic cleaning work?

The machine generates ultrasonic waves that cause cavitation—rapid formation and collapse of tiny bubbles in the liquid. This scrubbing action reaches even the smallest crevices of the items being cleaned.

What materials or items can be cleaned using ultrasonic machines?

Ultrasonic cleaning machines are suitable for jewelry, medical instruments, automotive and industrial parts, delicate electronics, surgical tools, and plastic components.

Are ultrasonic cleaners safe for delicate items?

Yes, ultrasonic cleaning is gentle yet effective, removing dirt and contaminants without scratching or damaging delicate surfaces.

Do ultrasonic cleaning machines require special maintenance?

Minimal maintenance is required. Regular cleaning of the tank and periodic inspection of the transducers and power supply ensures smooth performance.

Can ultrasonic cleaning remove grease and oil from engine parts?

Yes, specialized ultrasonic cleaning machines are designed to remove grease, oil, carbon deposits, and other stubborn contaminants from engine and industrial components.

How do I know which ultrasonic cleaning system fits my needs?

To choose the right ultrasonic cleaning system, you should consider factors such as the type of items you need to clean, the required tank size, the appropriate ultrasonic frequency, and whether heating options are necessary. It’s also important to decide if your application requires a multistage setup or a conveyorised system for continuous cleaning.

Does Cleanstar Machines provide installation and service support?

Yes, as a reputed ultrasonic cleaning machine provider in Pune, we offer installation, authorized AMC, and service support to ensure long-term machine performance.

Ultrasonic Transducers

Customizable Cleaning Parameters

Material Compatibility

Thorough and Precise Cleaning

Efficiency and Time Savings

Medical Instrument Sterilization: In the healthcare sector, maintaining cleanliness and sterility is paramount. Ultrasonic cleaning machines play a crucial role in sterilizing medical instruments with intricate surfaces and complex geometries. The ultrasonic waves generated by these machines reach even the tiniest crevices, ensuring a thorough and effective cleaning process.

Electronics Manufacturing: Precision is the key in electronics manufacturing, and any residues left on electronic components can lead to malfunctions. Ultrasonic cleaning machines offer a non-destructive and efficient solution for removing contaminants from delicate electronic components, ensuring optimal performance and longevity of electronic devices.

Automotive Parts Cleaning: As ultrasonic cleaning machine manufacturers, we recognize the significance of maintaining automotive parts in pristine condition. Ultrasonic cleaning is extensively used for removing grease, oil, and other contaminants from automotive components, enhancing their performance and contributing to the overall efficiency of vehicles.

Aerospace Industry: In the aerospace industry, where precision and reliability are non-negotiable, ultrasonic cleaning machines are employed for cleaning critical components like aircraft engine parts. The ability of ultrasonic waves to penetrate intricate structures ensures a thorough cleaning process, meeting the stringent safety standards of the aerospace sector.

Jewelry Cleaning and Restoration: Jewelry, with its intricate designs and precious materials, requires special care in cleaning. Ultrasonic cleaning machines provide a gentle yet effective solution for removing dirt, oils, and other residues from jewelry, restoring their shine and luster without causing any damage.

Optical Lens Cleaning: In optics, precision is essential for maintaining the clarity of lenses. Ultrasonic cleaning equipment is employed in cleaning optical lenses, microscopes, and other precision optical instruments. The technology ensures a residue-free cleaning process, contributing to the overall performance and longevity of optical equipment.

Food and Beverage Industry: Maintaining hygiene standards is critical in the food and beverage industry. Ultrasonic cleaning machines find applications in cleaning various equipment used in food processing, ensuring that contaminants are thoroughly removed without compromising the quality and safety of the products.

Print and Graphic Arts: Print rollers and other components in the graphic arts industry require meticulous cleaning to ensure high-quality prints. Ultrasonic cleaning machines offer a precise and efficient solution, removing ink residues and contaminants from printing equipment without causing any damage to the delicate components.

Firearms Cleaning: In the firearms industry, where precision and reliability are paramount, ultrasonic cleaning machines are employed for cleaning gun parts. The technology ensures a thorough cleaning process, reaching even the smallest crevices, contributing to the overall maintenance and longevity of firearms.

Historical Artifact Restoration: Preserving historical artifacts requires specialized cleaning techniques. Ultrasonic cleaning machines, with their ability to provide a gentle yet effective cleaning process, find applications in restoring and preserving delicate historical artifacts, ensuring they stand the test of time.